Ask Peter's AI chatbot about the Vineyard Plant Whisperer

The submit box below, is a general AI Model trained on all information available on the internet as of December 2021.

Take the response with a grain of salt because AI chatbots make stuff up. The industry calls it hallucinations.

With fine tuning and Retrieval Augmented Generation(RAG), the answers are much better.

We have an enhanced AI chatbot that knows more about the vineyard solutions we are implementing. Our RAG uses vineyard research papers and website articles CCA plans to incorporate into it's "Plant Whisper" AI driven robotic platform. If you'd like to try it please contact us. As it require an login account.

Example questions for Meta's Llama 3 70 billion parameter LLM general internet trained chatbot:

- What are the biggest issues facing grape growers?

- How to plant stresses effect wine quality and grape yields?

- What does it cost to start a vineyard?

- Tell me how UVC light can treat downy mildew?

- Explain AI emerging capabilities in chain of thought, Agents and text to action and how they will revolutionize grape production and the way vineyard research is conducted.

- What is high throughput phenotyping and how can it help me grow better wine grapes?

Ask your question and say "enter that".

You have to wear ear buds or mute speech output. Otherwise the chatbot will hear itself and enter what it saying into the prompt text box. Mute speech output

Peter James

Developer of the Wine Grape Whisperer

“Any sufficiently advanced technology is indistinguishable from magic.”

Athur C. Clarke

The fundamental approach the Plant Whisperer is using to converge on working autonomous robotic tasks and on optimal grape growing practices is called genetic algorithms. It follows the same principals as biological evolution. It competes many siblings against each other, picks the best performers and crossbreeds them for the next generation of competitors. Over many generations, the algorithm converges to near optimal solutions.

In the case of robotic tasks this process happens quickly (less than a year). When it comes

to plants, we can't afford to wait a year to harvest and pick winners for each generation, as that would take at least 50 years to converge on optimal solutions, if not longer. So, the Plant Whisperer approach is to use high throughput phenotyping to watch and listen to the plant for signs a various genes being expressed. A cultivar is a single genotype. But a single cultivar will look and perform differently based on the conditions it is grown under. Nutrition, climate, disease, drainage, air flow and stresses all effect which genes are turned on and which proteins (ie. RNA) are produced in the plant. Some plant inputs can express genes quickly like leaf curl from heat, to minutes to days.

It is these plant responses we will collect with AI sensor agents pass back to the AI. The AI then decides what the significances of the sensor data are and how it is correlated to various gene expressions. The AI then decides on which grow parameters to alter and implements these across many plants in many vineyards.

For instance the timing and to what extent a grower defoliates around fruit clusters effects yields and sugar production.

We will use genetic algorithms to adjust the timing, which leaves to remove and how many while taking into account light levels, plant transpiration, sugar content, etc to converge on optimal defoliation based on weather predictions and other factors.

Depending on spacing, there are 1,000 to 2,000 vines per acre. If we can get 100 5 acre vineyards to participate in the USDA study, that's at least 500,000 plants to participate in the evolution to optimal production. Each grower will be able to set guard rails on to what extent the plant inputs and stresses will be applied to their crops and to which ones.

Growers will also set weights on which goals they want for their vineyard. ie. maximize production yield, reduce effect of drought stress, reduce crop losses due to disease or pests, increase/reduce production in certain phytochemicals and sugars, etc.

Most of the parameters effecting genetic algorithms will be controlled by mother nature. Our Plant Whisperer AI will learn how each of these in combination with conditions under a growers control, impact the achievement each grower's goals.

Using low cost and portable nanopore streaming technolgy, we can analyze DNA, RNA and gene expressed protiens to drive breeding prgrams to optimal cultivars for every vineyard's unique conditions.

Order out of Chaos

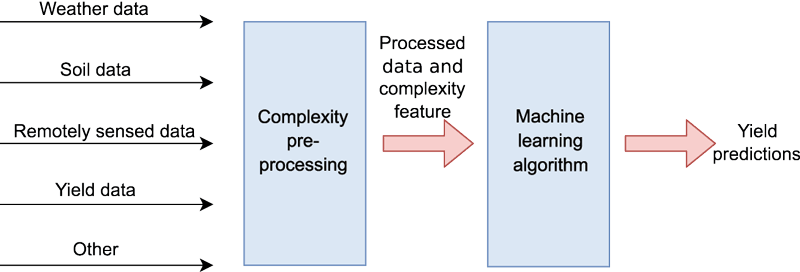

Schematic depiction of the proposed example. A multitude of data is fed into the preprocessing. The complexity-based preprocessing discards noisy data and adds a complexity feature to relevant data. A machine learning algorithm is then employed to predict yields.- Sebastian Raubitzek and Thomas Neubauer (Vienna University of Technology)

We believe biological and other natural systems, like weather, can't be

well understood using a deterministic physics paradigm. Rather these systems

are, as Ilya Prigogine termed them, disapative structures. The complexity of

growing high quality wine grapes is better understood when modeled as dissapative

structures using Chaos Therory. Following the "It Takes One to Know One" doctrine, AI

and particularly large language models are a mix of chaos and order and have

the capacity to uncover hidden order from the complexity that is grape growing.

We intend to build an AI and train it in all the data the AI can gather about

grapes and wine making to provide a deeper understanding of the process of

growing them and making wine.

Rather than design and conduct narrowly focused research on some aspect of

growing grapes, we propose to build a platform to include all human knowledge

about grapes and as many means of uncovering more data about the process.

This approach is outlined in,

"Machine Learning and Chaos Theory in Agriculture"

Kenshi Sakai describes Chaos Theroy methods to analysis Ecological and Economic AG 20 years ago.

I was getting tried of checking to see if a germination tray was drying out. I noticed a reflection off the

surface of the water. The reflection was getting smaller as the tray dried out. So I asked the Plant Whisperer,

if it could watch it for me and let me know when it was time to add water.

The Plant Whisperer generated the program above. The changing numbers on the left are the remain pixel area of the water. The right static number as the original water reflection area. When the current reflection area gets to a certain percentage of the original area, the Whisperer sends me a warning,

We intend to write a boat load of AI agents to watch and listen to vineyards and winery operations. I can't possibly write all that software.The AI Plant Whisperer will.

If you've always wondered what it would

be like to be Tony Stark, be a beta test site for the Plant Whisperer. We are providing an autonomous mower platform for vineyards. It will carry sensors to watch for disease, pests, nutrient deficiencies, chemical and stress induced gene expressions. The first year of service is on us.

And yes I hop out of bed every morning feeling a liitle like Tony Stark.

This 3D scanner provides precise plant component positions to guide robots for precision leaf surface electrostatic spraying, harvesting, cordon training, etc.

Our machine vision is trained to detect and outline weeds for non-pesticide removal. It will also be trained to detect, classify and outline all disease conditions, pests and nutrient defincies.

This is a low power laser prototype for performing many weed removal, pruning (cane & spur) and cutting tasks (fruit harvest & defoliation) in the field and in the processing center. A higher power laser will be deployed in production. Because the high powered laser cat cut instantly, the dwell time is so low there is no danger of starting a fire. We will be deploying a high speed targeted IR laser to identify and kill up to 20 insect pests per second.

This is an $80 sensor that tracks hand skeleton and forearm motion. It can be used to provide remote low cost labor from foreign countries or provide jobs to

disabled persons to perform fields and processing center work.

While others use it to train autonomous robot hands, a robot arm and hand are complex and expensive. We follow the KISS approach. Keep it Simple Stupid. The targeted tasks we need to perform in the field, can be performed with much simpler and lower cost devices. A pair of snipers or laser and a bowl to cup and catch the fruit are sufficient for harvesting. I pencil like tool to brush back leaves and snipers/laser are sufficient for defoliation and pruning.

Emerging "large spatial intelligence models" and "large behavior models" will allow us to more quickly and easily train robots to perform a wide array of field and research tasks like harvest, defoliation, precision spraying and pruning as well as research task like inspecting insect traps and collecting tissue samples.

Over the next five years these will be free open source technologies.

This is our robotic reel mower. It is a small fraction of the cost, weight and energy use of our previous electric ride-on rotary mower platform. It is so safe, you can stick your hands in the spinning blades and not get cut. It gives a better cut. Because reel mowers need to mow more frequently, we can use it as a platform to carry a wide array of sensors and robotic devices to perform virtually all labor tasks in the vineyard.

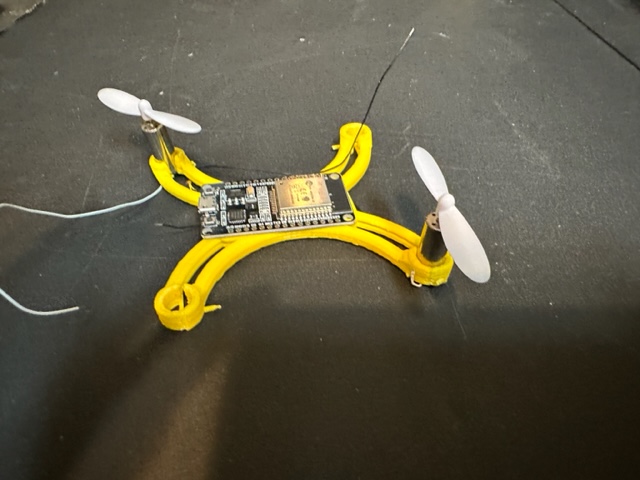

The mower platform will also serve as an aircraft carrier for a squadron of low cost 3D printed autonomous drones that will fly in close the each vine to inspect trunks, leaves and fruits.

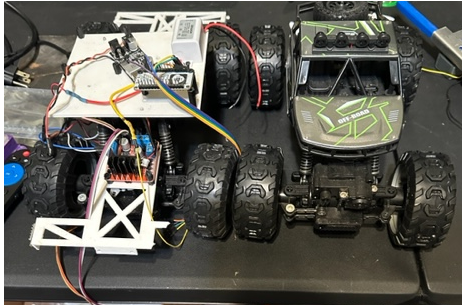

We will also release an army of low cost autonomous RC cars to inspect vine trunks for lesions and pests. it will also be able to leaves and fruits clusters from below adding 3D reconstruction of the vine when the mower and drone views are obscured.

This a $30 RC car we have modified to make autonomous. Due to their low cost, we can deploy a small army of these as sensor platforms at a very low cost. Using open source software, three cameras on the robot mower and SLAM maps created by the precision GPS controlled robots, these RC cars and and drones will be able to navigate very precisely around the vineyard.

We'll be modifying this low cost electro-static sprayer for precision applications of pesticides. By directing the robot to hold the nozzle close to the leaf surface the electrically charged droplets will only adhere to the leaf. This will great reduce the amount of pesticides used and keep it off the fruit.

We believe between UVC light treatments and precision spraying, vineyards can re-purpose their wide area spray fans to provide air flow to further mitigate humidity related fungal issues. Golf course place fans in dead air spots to prevent fungal outbreaks. .

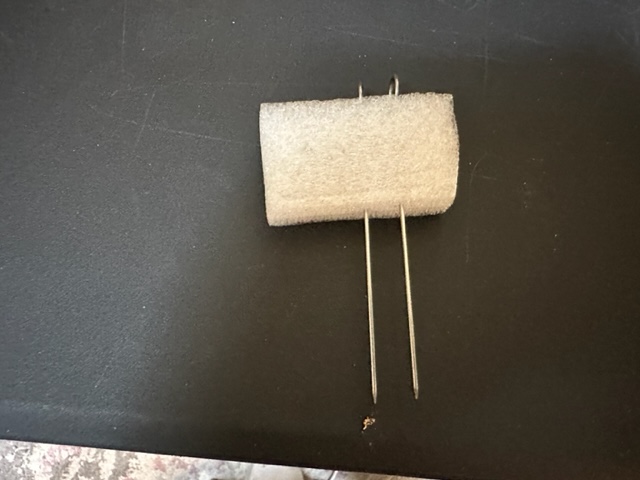

Soil Tester/sample pneumatic plunger. For soil sample collection and inserting test probes.

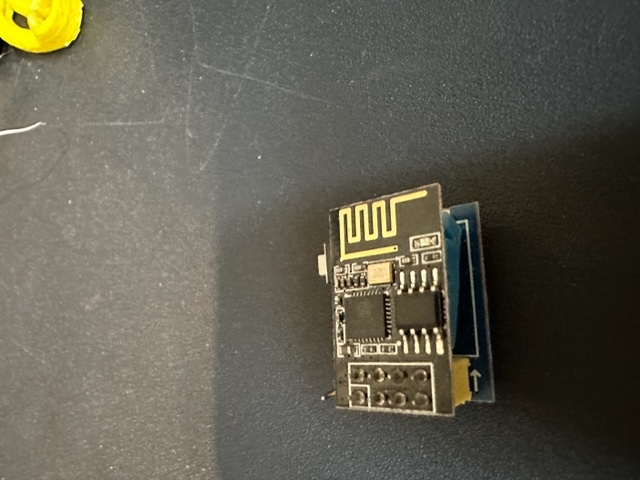

Wireless air temperature and humidity sensor. can use WiFi or bluetooth. Will be carried by robots and installed around the vineyard in stationary positions.

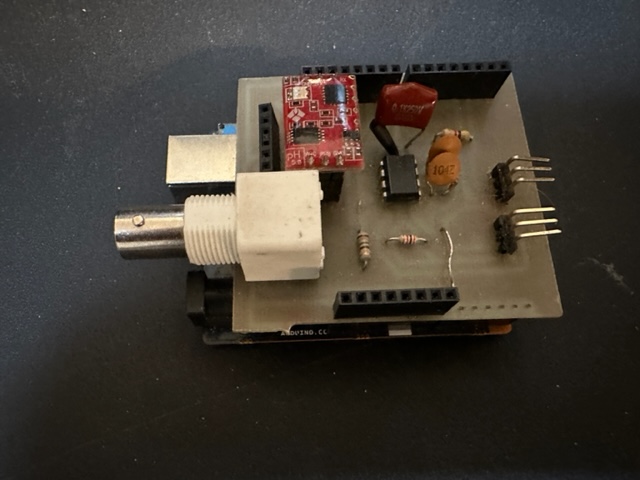

Poor man's EC and soil moisture probe. Commercial TDR EC/moisture probes run $100 and up. Using these probes and a low cost circuit will allow us to mount them on many more robots, to provide high precision soil mapping much more frequently. EC reflects the PH and salinity of the soil. Which in turn effects things like nutrient up take by the vines.

pH, EC and temperature test controller. We have a surface mount pick & place machine in-house to produce these in a much smaller footprint and cheaper.

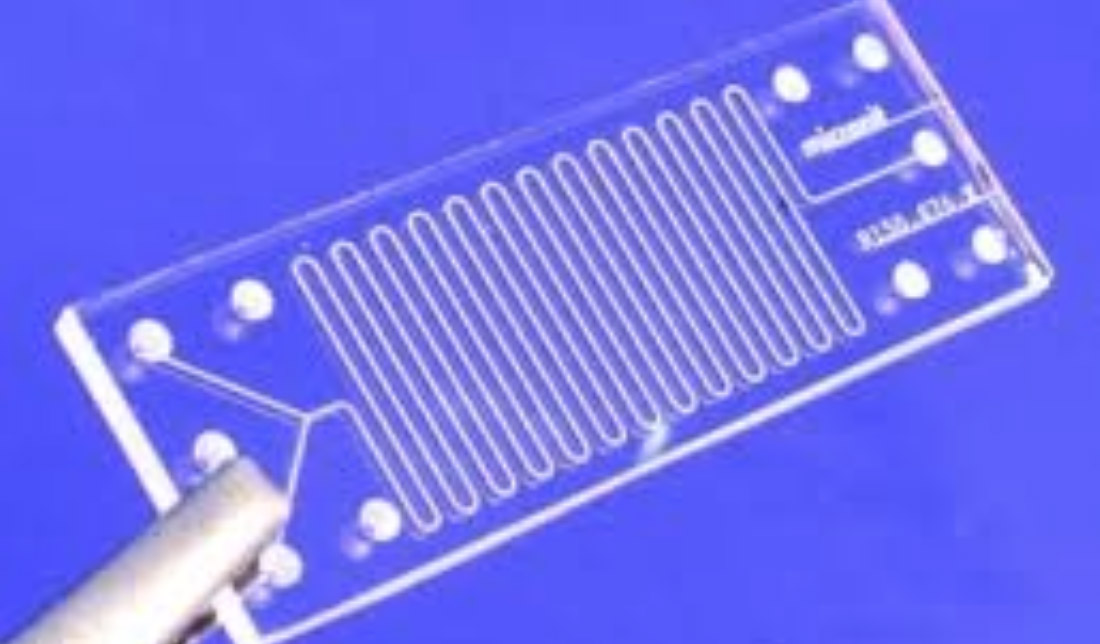

On securing sufficient SCRI funding will produce a 3D micro-fluidics handling device for processing soil, pest and plant tissue samples to perform liquid chromatography and use lab-on-chip technology for DNA analysis in the field.

For tasks like spraying and harvest requiring higher weigh capacities, we will use medium and high powered hub motor wheels to pull trailers, tankers. These will travel along the end of the rows and smaller robots will travel up and down the rows performing tasks.

In the cases where precision spraying and UVC light treatment is not adequate to control or prevent disease, the larger autonomous vehicle will tow the large sprayers. This will at least prevent worker exposure to those chemicals.

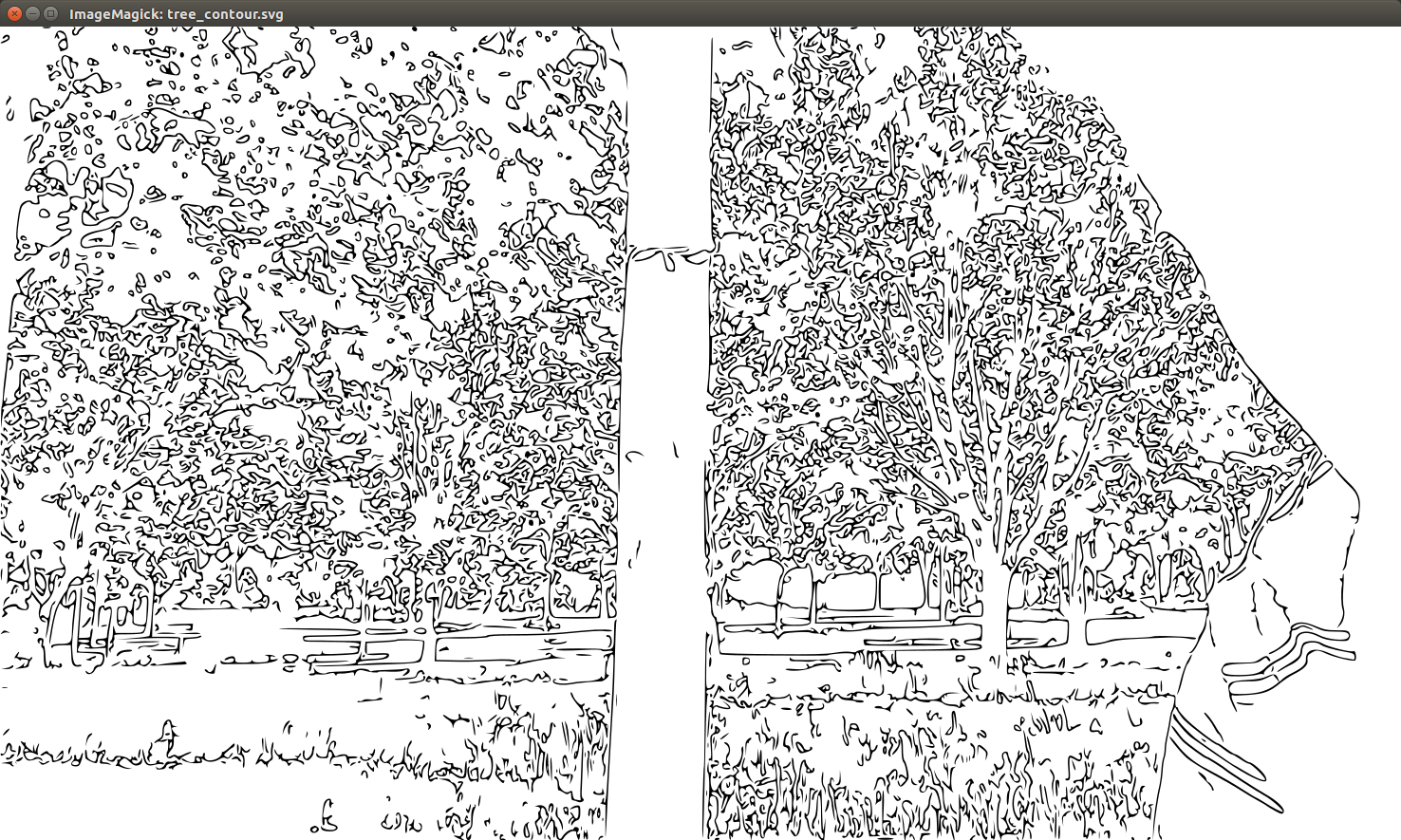

We will be building many forms of vision agents to feed the Plant Whisperer AI data. Edge detection of vine trunks can tell the AI many things. Such as triangulating the position of the robots, thickness of the trunk (ie. potential yield), help in registering other vision data like 3D, multispectral. We produced this image from a picture image at a local tree farm.

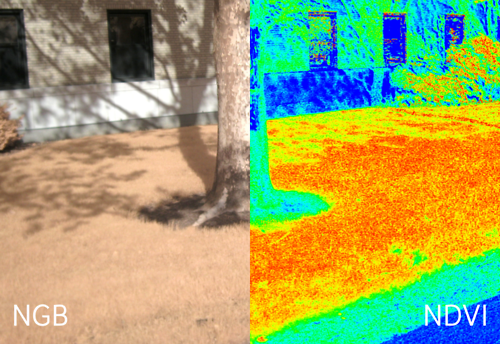

We will be scanning the vines, leaves and fruits in many spectrum both visible and non-visible. Using, normalized difference vegetation index (NDVI), red and near infra-red can tell what is foliage and things like heat and water stress. Green can disclose nitrogen content.

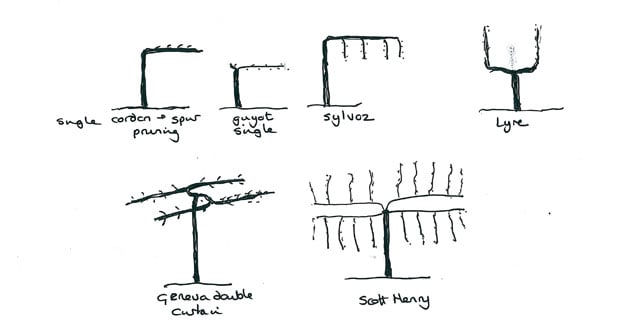

In order to optimize grape production, training the grapevine to achieve maximum absorption of photons, uptake of water and nutrients and air flow to prevent fungal disease. This needs to be in a manner the allow access to the vine and fruit to perform other task like mowing, weeding, spraying, trimming, defoliation and harvesting.

A typical vineyard n the east cost will have 6 foot spacing between rows and 4 foot spacing between vines.

However, if we remove the requirement for large machines and humans to access the vines, the vines maybe trained far more efficiently were one plant can double its production by supporting more branches(cordons). The number of fruit bearing branches(cordones) is also limited by the total water and nutrients that can be supplied by the main trunk. Which in turn a function of root zone and trunk size and health.

In order to increase the performance of space based antennas, genetic algorithms were used. Better antennas where produced but the shape of the antennas were strange and not what a human might come up with.

So using GAs to design the 3D layout of grapevines should be able to increase yields substantially. Especially, if small robots can get into tighter spaces to perform the needed work.

Similarly, all processes in vineyard operations and research can be optimized by genetic algorithms and genetive AI. What results from these optimizations, will no doubt be similarly surprising.